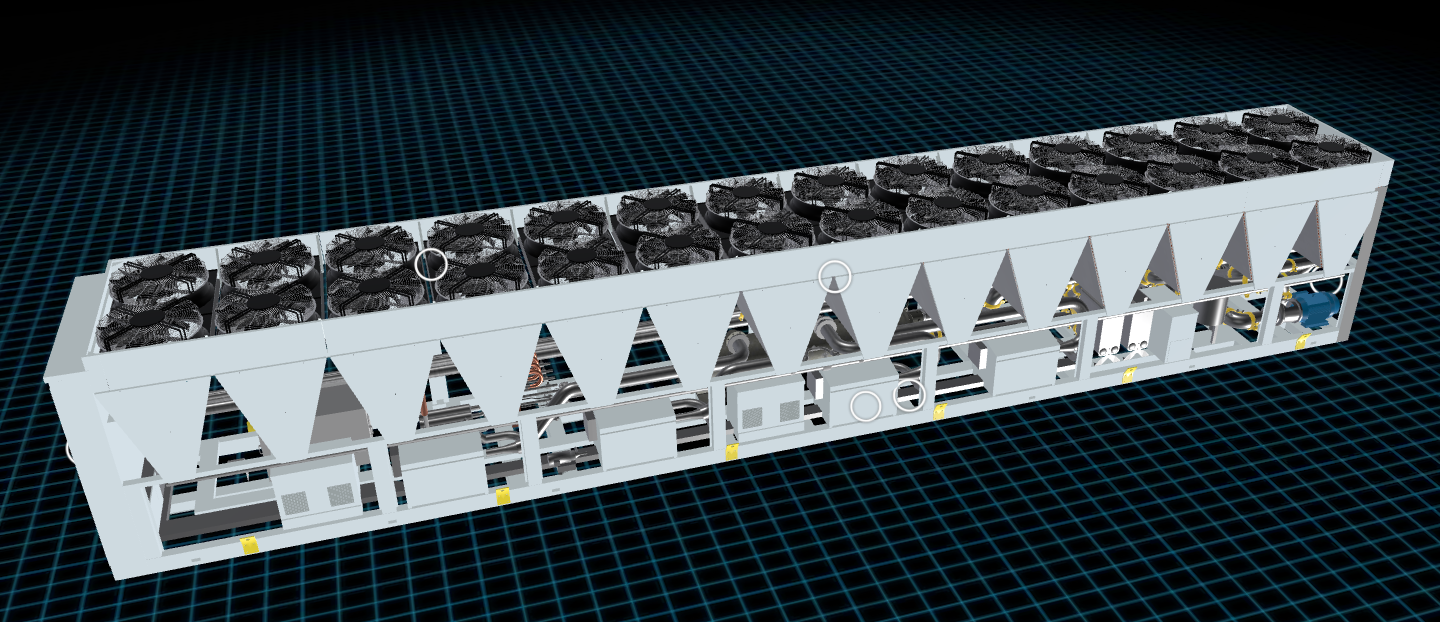

TurboChill™ DCS

Stainless Steel

The stainless steel design provides the hydraulic capacity needed for direct liquid cooling systems, which are increasingly used in high-density AI deployments across hyperscale, colocation and neo-cloud data centers.

- Corrosion-resistant material safeguards the integrity of the cooling loop, reducing contamination and build-up on the cold plates.

- Designed for high-capacity environments, maintaining structural stability under extreme thermal loads while enabling precise filtration and fluid management.

- Facilitates the elimination of in-rack, in-row and end-of-row coolant distribution units (CDUs), reducing system complexity.

- Frees up space in the data center hall for additional IT racks.

- Improves efficiency for optimized PUE.

- Seismic Design Category D.

Turbocor® Compressor Expertise

Airedale by Modine’s TurboChill™ DCS Stainless Steel builds upon 20 years of Turbocor® compressor experience and more than 50 years of data center expertise.

Full System Solution

Airedale by Modine solutions combine intelligent system integration with expert in-territory support, to deliver exceptional performance and reliability.

The dedicated data center engineering team at Airedale by Modine has designed the TurboChill™ DCS Stainless Steel to deliver exceptional performance, reliability and efficiency for mission-critical environments.

Efficiency

- Maintains structural stability under extreme thermal loads

- Precise filtration and fluid management

- Improved efficiency for optimized PUE

- Space saving design to free up space for additional IT racks

Performance

- Variable capacity control

- Operates effectively at very low-pressure ratios with liquid refrigerant pump installed

- Supply water temperatures up to 26°C (79°F)

- Oil free compressor for maximum heat exchanger

- Corrosion-resistant material to safeguard cooling loop integrity

Reliability

- Durable corrosion-resistant materials

- Optimized thermal performance

- Operational at up to 55°C (131°F) ambient temperatures (higher ambient profiles are available on request; unit excursion testing complete to 62°C (145°F))

- Seismic Design Category D compliant

- Up to 2MW cooling capacity

- Enables high-performance cooling for high-density AI application

- Eliminates the need for in-rack, in-row, or end-of-row coolant distribution units (CDUs), for improved efficiency

- A clean system approach, designed for the integration of the operator’s water treatment system.

- Materials selected for compatibility with, and to suit the specification of, the technology cooling system (TCS)

- Fully packaged product with on board pumps sized for a primary only system, allowing faster deployment and delivery

- Steel base, single-piece shipment

- Interface location positions for ease of installation

- Full controls optimization and integration

- Optional separate power supply to allow pumps to be UPS backed for system resilience

- Seismic-rated, allowing for deployment throughout territories

- UL certified and CE marked versions

- Layout and access allow for safe operation, maintenance and coordination with additional system equipment

- Capability of complete, comprehensive factory acceptance testing (FAT)