![]()

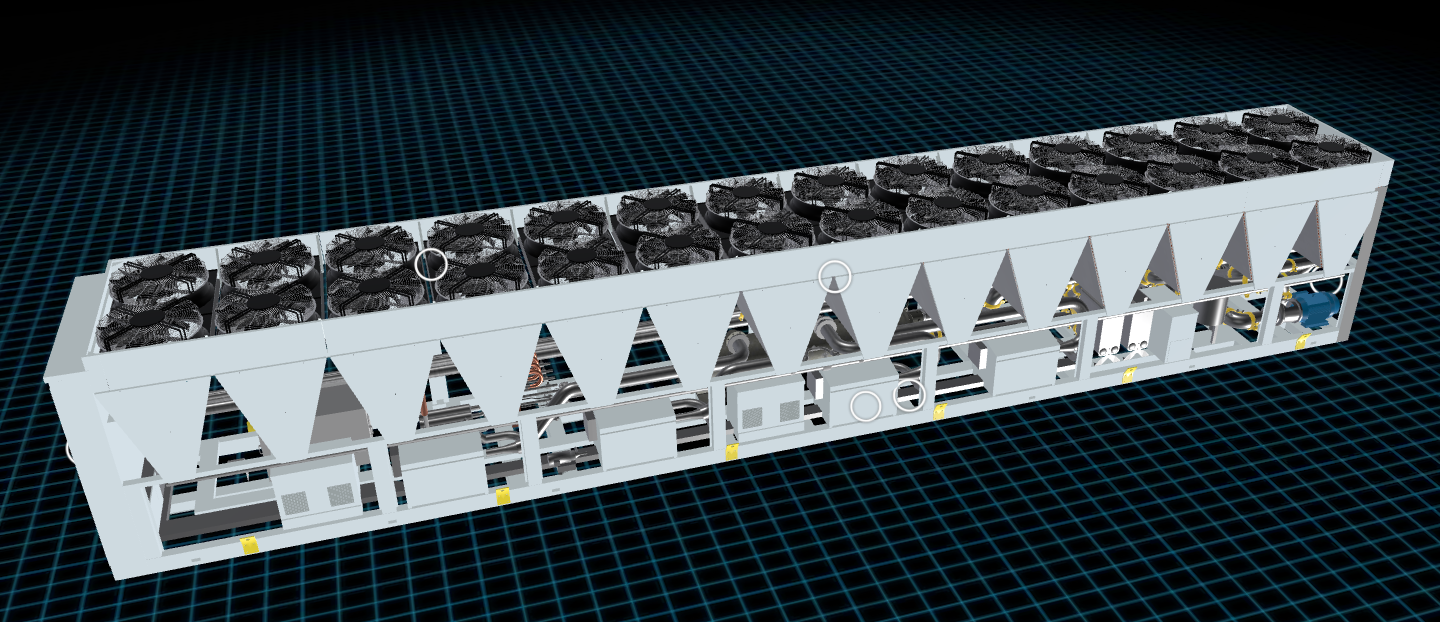

Ultra-high efficiency data center chiller, designed for colocation and hyperscale operation.

- Optimized for oil free, centrifugal Turbocor® compressor

- High capacity 800kW to 2MW

- Low GWP refrigerant R1234ze (GWP 1.37)

- Can deliver up to 36% energy savings over standard free cooling

- High ambient temperature operation, validated up to 55°C/131°F

- Enhanced Free CoolingTM technology for increased efficiencies

- Low sound operation

- Harmonic filtration

TurboChill™ DCS is the ultimate high capacity, energy efficient, air-cooled chiller solution, combining the unparalleled efficiency of oil-free centrifugal Turbocor® compressor technology, with the power saving benefits of free-cooling.

TurboChill™ DCS is frequently specified by data center operators requiring a high-performance cooling solution that leverages extended periods of free cooling without compromising operational integrity during mechanical cooling demand. Engineered with an emphasis on thermal reliability, acoustic attenuation and energy optimization, the system maintains stringent performance standards across varying load conditions and ambient profiles.

Customized cooling solutions

At Airedale by Modine, our design philosophy prioritizes flexibility over prescriptive solutions. TurboChill™ DCS reflects a baseline model, showcasing some achievable configurations to serve as a starting point for discussion. Our DCS engineering team collaborates directly with clients to develop customized solutions that align precisely with operational parameters and site-specific demands.

Data centers have evolved at an unprecedented rate, and so has the technology that cools them.

The dedicated data center engineering team at Airedale by Modine has redesigned the TurboChill™ DCS range from the ground up.

Re-evaluating every component for optimal efficiency, reliability and performance, design parameters have been pushed to create a chiller that not only supports the sustainability targets of our clients, but extends the boundaries of cooling technology in the data centers of today, and tomorrow.

Efficiency

- Economizer option for increased capacity for a given footprint

- Turbocor® compressors offer excellent full and part load performance

- One expansion valve per compressor to increase efficiency by improving expansion valve control at reduced loads

- Variable flow controls capability helps to reduce primary pump power draw

Performance

- Variable capacity control

- Operates effectively at very low-pressure ratios with liquid refrigerant pump installed

- Supply water temperatures up to 26°C (79°F)

- Oil free system for maximum heat exchanger

Reliability

- High quality components from leading global brands

- Incredibly strong case construction

- Powder coated paint process designed to last up to 20 years.

- Epoxy coated coils to maximize lifespan.

- Extensive validation testing in state-of-the art laboratories up to 55°C (131°F) ambient temperatures

- Sustainable refrigerant R1234ze (low GWP 1.37)

- Optimized oil-free centrifugal Turbocor® compressor

- Low sound operation

- Active harmonic filtration

- Wide operating envelope −25°C to 55°C (−13°F to 131°F)

- Supply water temperatures up to 26°C (79°F)

- 18 to 28 fan models

- Can deliver up to 36% energy savings over standard free cooling.

- Reconfigured V-block engineered to accommodate a larger free cooling coil.

- Larger fan to improve airflow.

- 3, 4 and 5 row coil options.

- Optional glycol containment provides both direct and indirect free cooling capability.

- Minimizes annual energy usage by reducing mechanical cooling in concurrent mode.

- Concurrent cooling operation allows the chiller to deliver free cooling

| 50 Hz | Notes | Units | TCF13R18K | TCF24R24G | TCC14R28K |

| Capacity | |||||

| Nominal cooling (gross) | (1) | kW | 985 | 1600 | 1850 |

| Nominal EER | (2) | 4.8 | 4.6 | 4.0 | |

| Ambient when free cooling | (3) | °C | 2.1 | 10.8 | N/A |

| Max. cooling (gross) | (1) | kW | 1500 | 1760 | 2000 |

| Max. cooling EER | (2) | 3.7 | 4.3 | 3.8 | |

| Dimensions | |||||

| Depth | H | mm | 2844 | 2900 | 2844 |

| Height W mm | W | mm | 2200 | 2200 | 2200 |

| Width | L | mm | 10550 | 14385 | 16207 |

| Mass – machine/operating | kg | 15080/16600 | 17171/18736 | 12630/13161 | |

| Unit | |||||

| Water volume | l | 1520 | 1565 | 531 | |

| Nominal water flow rate | l/s | 23.5 | 25.7 | 44.2 | |

| Nominal airflow | m³/s | 94.8 | 140.7 | 176.0 | |

| Max. airflow | m³/s | 143.6 | 169.5 | 234.8 |

(1) Nominal cooling capacity and nominal EER is at 20/30°C water and 35°C ambient, 100% water.

(2) Based on total input power of compressors and fans.

(3) Ambient when the total nominal cooling capacity can be met with free cooling alone, free cooling based on 25% Propylene Glycol contained loop.

(3) TCF13R18K based on 2 row free cooling coil data, TCF24R24G based on 4 row. Other coil configurations available please contact Airedale by Modine.

| 60 Hz | Notes | Units | TCF13R18K | TCF24R24G | TCC14R28K |

| Capacity | |||||

| Nominal cooling (gross) | (1) | TR | 280 | 370 | 441 |

| Nominal EER | (2) | (Btu/hr)/W | 11.9 | 10.7 | 11.5 |

| Ambient when free cooling | (3) | °F | 35.8 | 56.2 | N/A |

| Max. cooling (gross) | (1) | (Btu/hr)/W | 404 | 384 | 530 |

| Max. cooling EER | (2) | 10.5 | 10.8 | 10.4 | |

| Dimensions | |||||

| Depth | H | in | 112 | 114 | 112 |

| Height W mm | W | in | 87 | 87 | 87 |

| Width | L | in | 415 | 566 | 638 |

| Mass – machine/operating | lb | 33246/36597 | 37856/41306 | 27844/29015 | |

| Unit | |||||

| Water volume | gal | 402 | 412 | 140 | |

| Nominal water flow rate | gpm | 372 | 407 | 586 | |

| Nominal airflow | CFM | 200870 | 298126 | 369007 | |

| Max. airflow | CFM | 304271 | 359150 | 497606 |

(1) Nominal cooling capacity and nominal EER is at 68/86°F (20°C/30°C) water and 115°F (46.1°C) ambient, 100% water.

(2) Based on total input power of compressors and fans.

(3) Ambient when the total nominal cooling capacity can be met with free cooling alone, free cooling based on 25% Propylene Glycol contained loop.

(3) TCF13R18K based on 2 row free cooling coil, TCF24R24G based on 4 row coil. Other coil configurations available please contact Airedale by Modine.