Time to split? Moving away from specifying splits, VRFs and VRVs

Consultants may have to consider moving away from specifying splits, VRFs and VRVs as refrigerant regulations continue to tighten and public attitudes change.

By Darren Farrar, Marketing Manager at Airedale International

I asked my mum if she knew what air conditioning was the other day. She didn’t. So I asked “when you and Dad are on holiday and you’re staying in a hotel…when you turn the air con in your room on, what do you think is happening”?

‘Well there’s an air vent in the room and it blows out cold air.’

‘Where does that cold air come from?’

‘Erm…refrigeration? Cold pipes?

‘How do they get cold?’

‘Er..Electricity?’

Now I’ve not conducted a survey but I would hazard a guess that a lot of people not in the HVAC world would share this view; that air conditioning is nothing much more than fans blowing air around. It certainly doesn’t help my cause when I tell strangers where I work.

“Oh, that’s…interesting”

Now, why does this matter? Because we’re in the HVAC world and we know that the truth is actually far scarier:

Behind the air vents in your hotel room is a high pressure refrigerant gas that is piped all around the building. The gas usually used is 2,000 times worse than CO2 in terms of its contribution towards global warming. But don’t worry, it’s being gradually phased out in favour of gases that are only a few hundred times worse than CO2. Oh…and they’re mildly flammable.

We are in an age of self-enlightenment, where sustainability has been shunted to the front of the nation’s mindset by activism and the very real prospect of climate disaster. The fashion, automotive and food Industry for example have all faced up to their scrutiny and in response, made changes such as the reduction of single use plastics, sourcing sustainably and providing environmentally friendly alternatives. Air conditioning as an industry hasn’t really faced such scrutiny yet, where the public’s gaze will be laser focused on our practises. But it will, that we can almost guarantee.

Air conditioning is quickly becoming a societal necessity, if not a basic human right. It will soon start to permeate homes as well as businesses and as we grow as an industry, the HVAC world will become a target for mainstream media and mainstream opinion.

Who’s to say that in an era of cancel culture and a future where air conditioning is under the spotlight, that people may actively seek information from their hotels, shopping centres, places of work and gyms as to what refrigerant is used in their air conditioning system? This may be a little extreme a prospect, but it is an undeniable fact that peoples’ choices are increasingly being driven by sustainability…and we have only just begun.

Having given my mum the choice between a hotel building bursting with refrigerant 2000 times worse than CO2 or one a few hundred times worse but is mildly flammable, her response was people are “damned if they do, damned if they don’t”.

Fortunately, there is another way that we all know about. Reducing the refrigerant charge and moving it outside the building within a chiller is a proven and effective alternative. Using water as the cooling medium is not as efficient as direct expansion (DX) and it means more capital equipment in the form of larger chillers, but overall it is better for the environment. I put it to my mum that this was an option; that water could be used to cool their hotel room but this might result in prices rising slightly to cover higher running/capital costs.

Denise Farrar, Yorkshirewoman born and bred (we aren’t known for being frivolous with our money), said “that sounds good to me!”

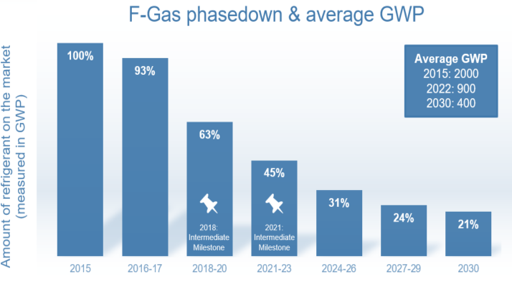

European F-Gas regulations will continue to put pressure on the supply of higher GWP gases like R410A. In 2021 we reach an intermediate milestone whereby the European market is expected to have 45% of the amount of refrigerant on the market (in GWP terms) than we had in 2015. This milestone will result in more manufacturers bringing out split / VRV systems using gases like R32. Indeed, there has been no paradigm shift towards chilled water systems yet.

BSRIA claim that this will start to happen in 2020 / 2021 though, as R410A supply becomes sparse and end-users / consultants come up against nervousness around using “mildly flammable” HFCs like R32.

The European F-Gas regulation is a phase down rather than a ban. Gases like R410A will still be available but it is incumbent on industry to use them in lower quantities, which will result in issues with price / supply as was seen in 2018 when the first intermediate F-Gas milestone came into effect.

Ready replacements for R410A like R32 are classed as A2Ls or mildly flammable. Whilst exhibiting much lower risk of combustion than highly flammable refrigerants like R290 (propane) some consultants and end users remain nervous. R32, with a Global Warming Potential of 675 times that of CO2, is also not the “end game” refrigerant the industry and the planet desires,but could serve as an interim solution until such a gas can be found and commercialised.

So what should I be looking for in a chilled water system?

Chilled water systems are becoming more and more efficient with the advent of heat pumps and low energy fan coil units. If you’re ready to make the switch, here’s some of the factors you need to consider.

Two or four pipe?

In a two pipe system (one supply line, one return line) the entire building is in either cooling or heating mode. There is less piping overall and CAPEX costs are less. However, 4 pipe systems offer simultaneous heating and cooling, including the subsequent ability to manage humidity.

In a chilled water system there may be glycol present acting as an antifreeze in the chilled water circuit. In a two pipe system with mixing of streams glycol can enter the hot water circuit and contaminate it.

Water expands and contracts with temperatures so pipework has to be designed to accommodate hot water and cold, maintaining correct pressures whilst allowing for changing volumes.

Where 2 pipe systems show benefits over 4 pipe systems is the energy used in heating; a dedicated HW coil is usually smaller than a CW counterpart whereas in a shared system the coil is larger, meaning lower temperature water can be used for the heating.

High efficiency chiller or heat pump

If a system uses water-source heat pumps instead of fan-coils, it can offer the advantages of a four-pipe system while relying on a single hydronic piping circuit. Water-source heat pumps can operate in either cooling or heating mode with a common water loop.

If a boiler is present for heating, then an air cooled chiller is the most likely source of chilled water for the cooling of the building. CAPEX costs can differ greatly depending on technology but so too can running costs – using oil free centrifugal compressors can save energy and offset the higher CAPEX quite quickly.

Ecodesign has set minimum requirements for chiller efficiencies that change again in January 2021. Ensure if your chiller arrives on site after this date it is Tier 2 compliant.

Low SFP

With stricter Part L regulations on the horizon only the most efficient air conditioning systems may be viable going forward. Look for systems with an SFP lower than 1.5 W/l/s to ensure compliance and deliver energy bills 1/3 of what you would see with a traditional fan coil arrangement.

Low noise and acoustic certainty

Aside from temperature, another serious and often overlooked issue in workplace environments is ambient noise. Even small increases in ambient sound can have a detrimental effect, as it increases the brain’s ‘fight or flight’ stimulus response.

Ambient noise doesn’t always mean loud machinery in a factory; it can also be things such as the hum of equipment, bad acoustics in offices, or the sound of an air-conditioning unit. Office workers are often subjected to it day-in, day-out, especially in offices w where there are older air conditioning systems with noisy fans.

Consultants should select low noise units, that is a given. What Is rarely considered though is the amount of separate noise sources present. Ducts and diffusers are all sources of noise so select systems with one factory tested noise source.

Summary

All in all, it’s unlikely we’ll see a sudden and massive decline in the deployment of split A/C systems, VRVs and VRFs just yet. The F-Gas phasedown will however create new challenges for the industry as the regulations continue to become more stringent and the market reacts…it is important to understand that there are alternatives and that water-based systems are up to the challenge.