Have filters in Data Centers become surplus to requirements?

Our calculations suggest a possible 14% increase in energy expenditure when comparing a like-for-like set up of cooling equipment inside a data center, where the only differential is the inclusion of internal filters on the fan walls. Paul Golding, Product Manager – CRAC CRAH Fanwall, ponders the question: why do some data center operators still specify filters inside their fan walls?

Our calculations suggest a possible 14% increase in energy expenditure when comparing a like-for-like set up of cooling equipment inside a data center, where the only differential is the inclusion of internal filters on the fan walls. Paul Golding, Product Manager – CRAC CRAH Fanwall, ponders the question: why do some data center operators still specify filters inside their fan walls?

It is no secret that data center servers kick out huge amounts of heat that have to be controlled to prevent operation failure. So critical is cooling within the data center industry that millions of dollars are invested each year in the development and implementation of technology to keep the servers cool.

It is no secret that data center servers kick out huge amounts of heat that have to be controlled to prevent operation failure. So critical is cooling within the data center industry that millions of dollars are invested each year in the development and implementation of technology to keep the servers cool.

With increasing awareness of the impact this level of mechanical cooling has on the environment, the industry is taking significant steps towards becoming more sustainable, demanding more efficient solutions from suppliers. With a huge emphasis on R&D from cooling solution suppliers, the technology employed within data centers has evolved. Beyond the use of high efficiency equipment to drive a PUE as close to 1 as possible, data center operators are also looking for low water usage, low GWP refrigerants, and air flow manipulation and management, such as hot aisle containment, increased operating temperatures and software monitoring as a means of improving the data center’s carbon footprint.

As part of this evolution, the popularity of high efficiency fan wall solutions within data center cooling has increased. Fan walls use pressure and air flow dynamics to condition the space, and are relatively basic systems, pushing conditioned air into the server hall. Operators tend to employ a mix of traditional down flow units and fan walls, with the fan wall removing the need for raised floors, improving air distribution and reducing site deployment times.

The typical build of a fan wall includes air inlet from a maintenance corridor, a fan, and a coil, with space in between the fan and the coil to enable the air to be distributed evenly. Filters can be fitted before or after each fan – their purpose is to keep the unit free of particulate matter that might build up and cause a malfunction in the server equipment. Understanding that a single fan wall unit might house anything between 2 and 12 fans to distribute air across the water coils, and depending on the size of the data halls, there can be anything up to around 15 or even 20 fan wall units in one data hall, that amounts to a lot of fans and subsequently, a lot of filters.

Prevention is better than cure?

Of course, filters are not there by accident. Filtration manufacturers rightly state that poor air quality within a data center can lead to the corrosion of units. They state that gases in the air such as sulphur dioxide, hydrogen sulphide and particulate matter could enter the space via poor ventilation units and/ or open doors, and this can lead to the reduction in performance or even breakdown of cooling units. These pollutants can also break down computer circuitry and cause malfunctions in the flow of electricity. Another less known fact is that air pollution accelerates the accumulation of salt in the air and that salt is corrosive. The risks presented by debris entering the data hall make filtration an essential component of data center operation, with some filtration manufacturers and engineers therefore arguing that filters within units should be compulsory. If dust and dirt were to get into the coils it could cause a failure or degradation in efficiency to the cooling systems, which in turn could stop the servers functioning, and this would be a crisis situation, risking loss of business activity and/ or loss of data. A risk too great to take when a simple filter can prevent this, hence why we have a trend for filters covering the coils in data center fan wall units.

Evaluate the risk

However, it is reasonable to suggest that this risk only exists when there is a risk of debris entering the space in the first place. The way most data halls are arranged today means that the chances of having debris in the space can be significantly minimised by an alternative arrangement of plant equipment. This then begs the question of why so many filters, and is there a better way to manage risk and server availability that doesn’t impact the planet as much?

- Is it reasonable to propose that we might be putting filters in out of habit, fear and precaution as opposed to necessity.

- Is there an alternative, more sustainable solution which might better serve today’s objectives?

To consider this, we have to consider how debris might enter the building and consider how that is being managed today.

Positive pressure

Most data center halls have a positive pressure, with an externally fitted air handling unit as part of the system, there to pressurise the room so that when an external door is opened, air leaves the room, rather than entering the room. The purpose of this positive pressure is to ensure that minimal, if any debris or dirt is brought in.

Fresh air filters

Fresh air enters the internal space, via an external air handling unit. Filters are fitted on fresh air units to remove any debris in the external air before it enters the internal space and as such once the air is inside the building, it is clean and free of particulate matter. These filters are considered to be essential to clean the air entering the data hall.

Removal of false floors

False flooring can be complex and not very long lasting; they often need re-configuring to suit updated plant equipment, especially if the new plant is heavier than the original equipment that the floor was designed for. False floors aren’t likely to withhold an earthquake and so have generally been unpopular in risk zones. Finally, from a day-to-day, practical perspective, false floors carry with them significant maintenance and cleaning requirements, with the high pressure space under the floor creating a lot of dust and build up. High levels of internal filtration was essential to manage this dust.

Due to the complexities that come with false floors, data centers have moved away from them and tend to work with a solid floor solution, which amongst other things, allows the operator to employ more frequent, lower cost cleaning regimes, with a simple, regular floor clean. The introduction of solid floors has therefore removed the need for the high level of filtration that false floors demand.

Air Locks

An airlock entry system is another method that can be employed as a means of reducing the risk of contaminating the air inside the data hall when people enter and exit the building. The air lock is in effect an enclosed space between two interlocked doors, allowing for a controlled transition between the external environment and data hall. Because this does eat into the floor space and overall design of the building, it isn’t always favoured, or indeed necessary if other methods are employed, but it is an option.

Unmanned spaces

With remote monitoring systems capable of detecting faults beyond that of a human eye, data centers are more and more becoming unmanned spaces, with the exception of occasional maintenance visits. Knowing that humans create the vast majority of dust, keeping people out of the space allows the already filtered air to remain free of debris.

Air scrubbers

Air scrubbers are high efficiency, low operational cost units designed to clean the air. They can sit within a data center and recycle the air already in there, removing any traces of carbon that might have shed into the air from plant equipment. Air scrubbers provide a failsafe, belt-and-braces reassurance that the air within the data space (that was cleaned at the point of entry, and hasn’t been contaminated by humans, false flooring systems, or by the opening of doors), isn’t at risk of being polluted by any other rogue elements that have inadvertently entered the space. Much smaller in scale, they require less energy input than the additional power requirement operating every fan wall with filters, making it a more efficient solution.

The pros and cons of filters within a fan wall unit

Maintenance

The filters within any unit, by nature of their purpose, need to be regularly cleaned and changed. In a unit where filtration is essential, it makes sense to do this and changing filters is built into an annual service check to minimise the risk of breakdown. Often filters are changed even if they are not dirty, because it makes sense to do them during the routine service visits, as opposed to calling mechanics back to change filters at ad hoc intervals.

Environmental impact

This means that within a data center, there could realistically be over 200 filters changed every year. Multiply this over every data center in a region, and that adds up to a lot of disposable products that ultimately have to go to incineration, to remove the contaminated particles they have captured.

Energy Efficiency

Filter suppliers are no doubt doing more these days to reduce their carbon footprint, considering things such as what chemicals are used in manufacture, how they are packaged for transportation and how much energy they use in operation. One manufacturer sites that in a life cycle analysis of a filter, 70% of the cost can be attributed to its operation and for this reason and points to this as the justification for guidelines around filtration efficiency. Working within EN16890 filtration classifications, manufacturers are able to select the most efficient filter that meets their filtration requirements.

What are the real term benefits of removing filters?

Recognising that the purpose of the filter is to clean the air for healthcare and environmental benefits, filters definitely have their part to play and it is important to do a cost/ benefit balance to identify the right filter for the job. The problem we are considering is how necessary is a high level of filtration, with associated energy usage and other elements that lead to its carbon footprint, in an already clean data hall?

Energy use

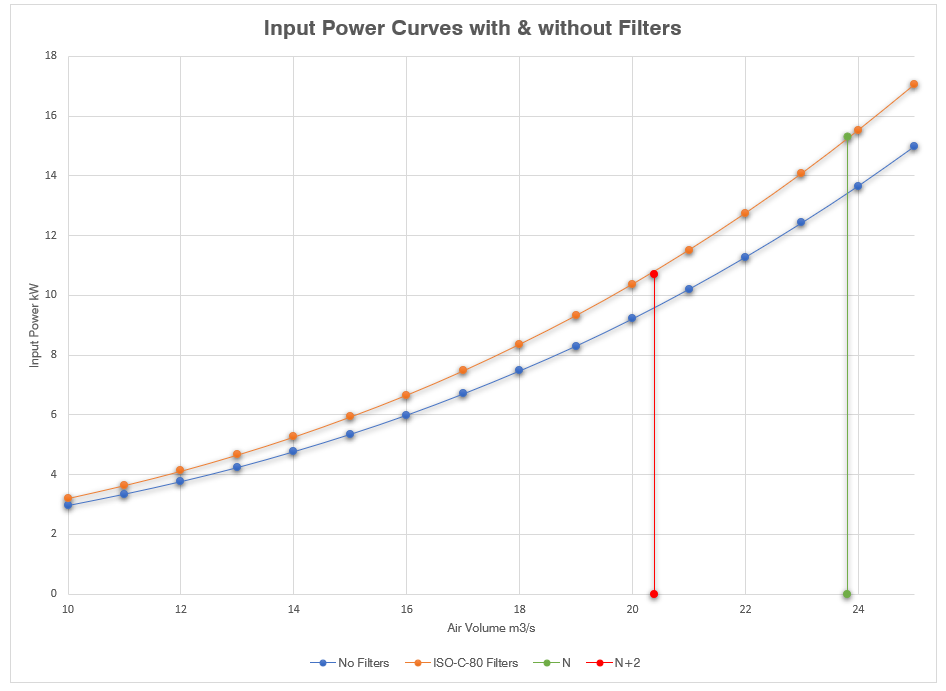

Given the large volume of filters in a large number of data centers, over say a 10 or 15 year lifespan of a unit, the extra energy expenditure can add up to a notable cost for the operator, and again in terms of energy, a considerable cost to the planet. As an example, we ran some selections for a theoretical 4MW data hall with N+2 redundancy. In N+2 operation the data center with filters has a fan input power of 143kW compared with no filters at 125kW, so circa a 14% increase in fan power. This is a significant cost to a data center where the majority of the time all units will be operational.

Are there are any risks to removing filters from fan walls?

The removal of filters from fan walls needs to be carefully managed, from a unit and system perspective. This is because if a filter is removed, there is a small risk of the coil working as a filter and therefore it is recommended that the fin space on the coil is adjusted to be bigger than when filters are used. This is so it doesn’t trap any smaller, rogue molecules that might interfere with its operation. Adjusting the fin space to complement not having filters also helps with coil pressure drop, but it must be changed within the specifics of the project and requires consideration.

Filters can really only be removed if all of the afore mentioned points around how the data hall air is cleansed are employed, to ensure that there are alternative measures in place to filter and maintain the clean air. These need designing into the cooling system early on to ensure they work with the space and are effective.

The other risk to be aware of are that at the point of commissioning, there is likely to be a lot more debris and therefore a basic filter media needs to be employed to manage that situation and protect the equipment. Once the data hall is operational this temporary filtration measure can be removed, providing the other air filtration controls are in place.

Conclusion

With sustainability taking equal priority as performance, we need to look for operational set ups within the data center that deliver on both objectives. This starts with efficiency of equipment and forces us to throw away the manual and re-evaluate where we are today.

There is no point doing things ‘as they have always been done’ if it is only fear driving the decision. We should not be taking risks either, but instead take educated, measured steps based on the evidence and experience we have gathered as technology has evolved.

There is an argument to suggest that with positive pressurisation, filters in the fresh air supply, air scrubbers and a temporary filtration system at commissioning, an effective data hall can operate more efficiently and sustainably without filters in every fan wall. Less filters would lead to a reduction if the power requirement of the fan wall as demonstrated in our calculations, less waste from disposable filters, and a reduced need for the expense of filter maintenance, improving sustainability goals, without impacting on performance.

We are starting to see a shift in our collective thinking, with more data center operators making the decision to remove internal filters, but only if they are assured that their external filtration system is robust. This sustainable strategy adds no more risk, and reduces cost to their operation and the planet.