Carbon at all costs? Why water use in data centres needs to be part of the net zero discussion

In February, Airedale’s Daniel Burczyk presented at DCD’s Towards Net Zero global online conference. The session can be viewed here, but if you don’t have time to view on-demand, he has summarised the presentation as a blog article below.

Water is already a very stressed resource, and growing populations, intensive urbanisation and industrialisation are adding yet more strain. In 2015 the World Economic Forum in Davos listed “water crises” for the first time as the world’s leading threat, and this is not a crisis limited to developing countries. With the use of water in data centres increasingly coming under the microscope, the industry cannot ignore its critical role in tackling this global issue. Measures like PUE have helped steer the industry down a greener path and technological strides have been made in order to increase efficiencies, but it doesn’t tell the whole sustainability story.

Water is already a very stressed resource, and growing populations, intensive urbanisation and industrialisation are adding yet more strain. In 2015 the World Economic Forum in Davos listed “water crises” for the first time as the world’s leading threat, and this is not a crisis limited to developing countries. With the use of water in data centres increasingly coming under the microscope, the industry cannot ignore its critical role in tackling this global issue. Measures like PUE have helped steer the industry down a greener path and technological strides have been made in order to increase efficiencies, but it doesn’t tell the whole sustainability story.

When examining the evolution of data centre cooling and sustainability, it is important in to do so in the context of the global water crisis as well as wider carbon reduction initiatives. What are the issues with current systems that are adding to the industry’s water consumption? What needs to follow the era of adiabatics to make a real difference not only to energy usage, but also water conservation?

The data centre industry’s rapid expansion in recent years is well documented and shows no sign of abating. However, with great power comes responsibility. A recent report suggests that by 2025, data centres will consume one-fifth of all the electricity in the world. Stats like this have served to bring the sector under the spotlight and it has come under increasing pressure in recent years to reduce its carbon footprint and operate more efficiently.

The primary source of energy consumption in most data centres is cooling. This energy usage mainly comes from large industrial equipment such as pumps, chillers and cooling towers, which are used to regulate data centre temperature. It is important for the air conditioning industry to take its energy efficiency responsibilities seriously.

Measures like Power Usage Effectiveness (PUE) have helped steer the industry down a greener path and technological strides have been made in order to increase efficiencies, but PUE doesn’t tell the whole story. The use of water in data centres is increasingly coming under the microscope.

Global Water Crisis

We live on a blue planet…yet only 1% of the world’s water is useable. Growing populations, intensive urbanisation and industrialisation are putting strains on this 1% like never before. In 2015 the World Economic Forum in Davos listed “water crises” for the first time as the world’s leading threat and this is not a crisis limited to developing countries. Water is essential to achieving climate targets because climate change affects the availability, quality and quantity of water for basic needs such as industry and agriculture (UN, 2020).

As an industry we cannot ignore this.

Take the US for example. In all, data centers throughout the United States were projected to consume a combined 660 billion litres of water in 2020 (US Department of Energy report). In FY18, Google used 15.79 billion litres of water (Google, 2019). Some went to offices, but the majority was consumed by its global fleet of data centers. In FY18, Microsoft used 3.5 billion litres (Microsoft, 2018), also with the majority going to its data centers. A 1MW data center using traditional cooling can use around 25.55 million litres of water per year (Heslin, 2016) and less than a third of data center operators track any water metrics, with water conservation ranked as a low priority (Heslin, 2016). The Data Centre industry must take its environmental responsibility seriously, including water conservation and a combination of PUE & WUE is now essential for the industry going forward.

The Evolution of DC Cooling

Air-Side Optimisation

Around ten years ago, the optimisation (increase) of air temperatures was introduced as the latest way for data centres to increase efficiencies. At the time, many data centres ran at set points of 20°C to 22°C. The American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE) updated their guidelines for temperature and humidity operating ranges of IT equipment, in line with technology advancements and a focus on sustainability. Their updated “recommended” supply temperatures rose and included a much wider operating band called the “allowable” range, which represent the actual limits at which IT equipment should be subjected to. This gave data centre operators more flexibility in terms of temperature setting, with the caveat that outside the recommended range, there is an expected impact on reliability, defined as the “X Factor”.

Running data centres at higher temperatures reduced the cooling requirement and provided more opportunities for free-cooling. Airedale International pioneered this with the introduction of chillers specifically designed to take advantage of enhanced free-cooling opportunities, resulting in a lower cost of ownership for operators.

Adiabatic Cooling systems

The rapid growth of the industry in the last ten years resulted in a supply chain struggling to keep up. Chillers were facing serious issues as operators required a lot more from their cooling systems than was offered or available on the market. For some time, chiller operating limits and efficiencies were preventing the industry from achieving the PUEs that it strove for and, simply put, past efficiencies were no longer sufficient.

As problems with chillers continued, alternatives like adiabatic dry air coolers were taking advantage of elevated supply air temperatures to provide solutions without the need for compressors. Chillers, at the time, were extremely inflexible, and had relatively limited operating envelopes.

In recent years, air-side optimisation has been built on with the introduction of adiabatic cooling systems. This technique incorporates both evaporation and air cooling into a single system. The evaporation of water, usually in the form of a mist or spray, is used to pre-cool the ambient air to within a few degrees of the wet bulb, allowing cooler and more efficient operation.

The use of spray or mist means water use is significantly lower than with more traditional evaporative systems, but a conservative water usage estimate for a modern data centre employing an adiabatic cooling system would still be 500,000 litres /1MW/Annum. As data centres grow larger, this becomes a real concern, particularly in regions where water shortages have been identified as a threat.

The water usage itself is not even the whole story. This water still has to be stored and treated which increases capital costs and as with any mechanical equipment exposed to continuous water contact, cooling plant has been seen to suffer from increased degradation, putting strain on OPEX costs too.

Water Side Optimisation

Having recognised the need for cooling systems that provide something close to the efficiencies that can be achieved with adiabatic cooling, but with a more sensitive approach to water conservation, Airedale developed an innovative approach to data centre cooling, that takes the philosophy behind air side optimisation and evolves it further. Airedale call this Water Side Optimisation and it is proving its worth in many of the world’s leading data centres already.

The philosophy of Water Side optimisation is based on taking an optimised air environment and looking at what other variables can be adjusted in order to deliver more free-cooling. Assuming that the air within the data centre white space stays at the same temperature, the next step was to reduce the approach temperature whilst opening the difference between water supply and water return. Implementing innovations within the plant equipment means the supply and return air remain as before, but supply and return water temperatures are higher, thus the approach temperature is reduced. We see a fixed temperature difference of 12°C TD on the air side with the fluid side being opened out to 12°C and the approach temperature closing from 6°C to 4°C.

We achieve this via physical changes in the equipment and environment, like:

- Higher water temperatures, meaning less mechanical cooling

- Simplified air paths

- Ducted hot air return

- CRAC / CRAH with maximised coil surface area

- Free cooling coils with maximised surface area

- Free cooling chiller / DAC

- Smart controls with dynamic operation

Free-cooling chillers are matched to large surface area chilled water coils in either indoor CRAC units or fan walls. The air path is simplified using hot aisle containment, creating a pressure differential that draws cool air through the servers and out of the white space via ducts and back to the air conditioning plant via a common plenum. The air is introduced directly to the space via side wall diffusion, minimising air side pressure drops. This is all managed with an intelligent controls platform that monitors fluctuating demand within the white space and dynamically operates the system at its most efficient operating point.

- Lower waterside pressure drop

- Smaller pipework

- Wider free-cooling band

- No need for adiabatic spray & water storage

- Less mechanical cooling meaning more efficient chiller operation.

- Lower fan speeds meaning more efficient indoor unit operation.

- Lower pump power meaning more efficient water transfer.

- Large coil surface leads to increased cooling for less footprint (more cooling capacity per m.)

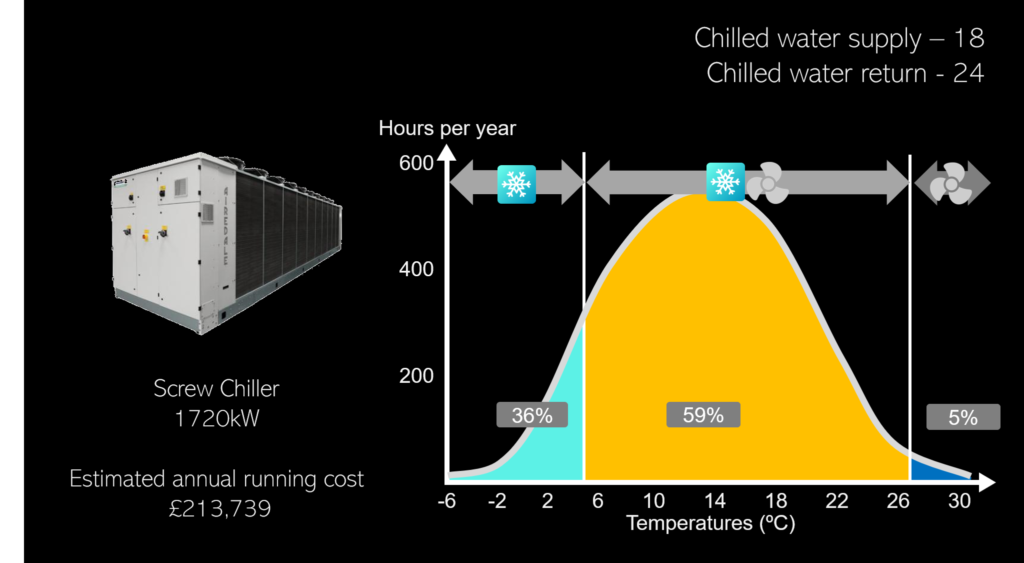

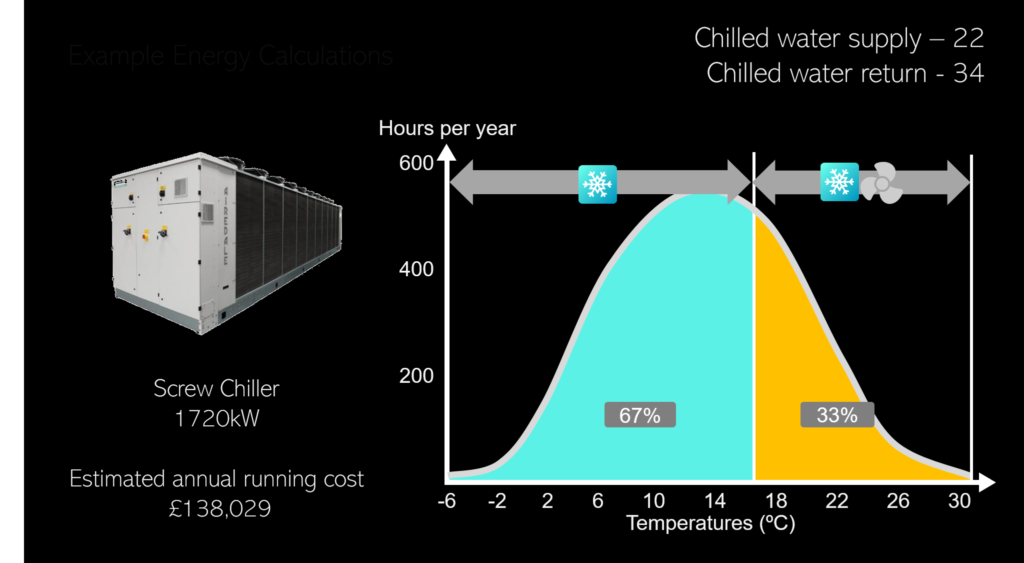

Based on average temperatures for London, an extra 2°C creates many more hours of free cooling. 14% more free cooling (59% in total) can be achieved with Water Side Optimisation, with all but 1% of the rest of the year being covered by concurrent cooling (a combination of free cooling and mechanical), giving huge benefits in terms of chiller efficiency. This system could provide free cooling for over 50% of the year in all of Europe’s major data centre hubs (London, Frankfurt, Amsterdam, Paris, Dublin).

Airedale’s Water Side Optimisation solution is in operation across Europe, offering considerable efficiencies. The graph below demonstrates this performance and how it can benefit the end user whilst minimising the impact on the environment.

Download our whitepaper on the future of data centre cooling now>

Daniel is a Solutions Specialist within the European Data Centre Team at Airedale International. He has two B. Eng. Degrees (Mechanical Engineering & Product Design and Development) and started his career working for two of Germany’s most respected brands, Siemens and Mercedes, before joining the HVAC world via SGL Systems. Here he gained experience working on designing bespoke HVAC solutions for offshore applications before first experiencing the data centre world at Barkell, where he was involved in designing custom Air Handling Units, including fan walls, at some of the UK’s largest facilities. He started his current role at Airedale in 2019 as part of their European expansion plans and has since worked on facilities ranging from 2 to 180MW, designing and specifying complete cooling solutions. With a very keen interest in leaving a better world for his three children, he is passionate about data centre sustainability and how critical systems like cooling can contribute to a greener future for an industry growing in both size and global responsibility.

Daniel is a Solutions Specialist within the European Data Centre Team at Airedale International. He has two B. Eng. Degrees (Mechanical Engineering & Product Design and Development) and started his career working for two of Germany’s most respected brands, Siemens and Mercedes, before joining the HVAC world via SGL Systems. Here he gained experience working on designing bespoke HVAC solutions for offshore applications before first experiencing the data centre world at Barkell, where he was involved in designing custom Air Handling Units, including fan walls, at some of the UK’s largest facilities. He started his current role at Airedale in 2019 as part of their European expansion plans and has since worked on facilities ranging from 2 to 180MW, designing and specifying complete cooling solutions. With a very keen interest in leaving a better world for his three children, he is passionate about data centre sustainability and how critical systems like cooling can contribute to a greener future for an industry growing in both size and global responsibility.