Green is the colour of money – how to make a sustainability programme stick in manufacturing businesses

As an air conditioning manufacturer we definitely feel the weight of responsibility when it comes to sustainability. Historically, because of the energy and refrigerant gases used within air conditioning products, the HVAC industry has attracted attention. On top of this, manufacturing processes currently use roughly one-third of the world’s energy.

As a marketer I’m one of the people at the company taking a lead on sustainability as it’s my job to reshape that narrative and help steer the ship strategically, listening to our clients and what they want.

We work heavily in the data centre market, which is an industry experiencing rapid growth at the moment and subsequently increasing its share of natural resources because of the vast amounts of energy consumed by servers and cooling systems. As a collective, they’re aware of their responsibilities. It’s an industry spearheaded by household names like Google, Amazon and Meta and as part of their sustainability commitments they’re passing some of that responsibility down the supply chain to companies like us. So as a company that’s growing and serving these industries, as a marketer I have to put sustainability front and centre of my role and therefore, it has to be front and centre of everything we do as an organisation.

Sustainability – First Steps

The first step is understanding and acknowledging that there is a problem. Being at the front, like the classic tortoise and hare story, can encourage complacency. 5 to 10 years ago we were leading the way in using lower GWP refrigerants and designing energy efficient products. We have a BREEAM very good rating for our factory, we have PV panels on our roof. However, times change. That just isn’t enough these days. There wasn’t a single “aha” moment. We did have a boardroom that hadn’t seen any new blood for a while, it was a bit short on fresh ideas. As we grew we took on people with more diverse experiences and views, I myself had worked for a company where sustainability was right at the heart of everything we were about. I think the combination of these new voices combined with growing customer demand for more sustainable solutions and partners meant that we had to renew our focus.

On top of this we see events like COP 26 getting huge media attention; big companies setting out ambitious goals and reforming their entire strategy around sustainability. As an experiment, look up the FTSE 100 and go to every manufacturer website listed on there…I guarantee sustainability will feature on the front page. We all have to recognise that just saying sustainability is no longer enough, it has to be tangible and lead somewhere. Once you set a goal you can build tactics around that. It’s not going to work if you just sit in the boardroom and say “we need to be sustainable”. With a target adopted and measurable objectives set, people become accountable in the same way they are for hitting financial targets.

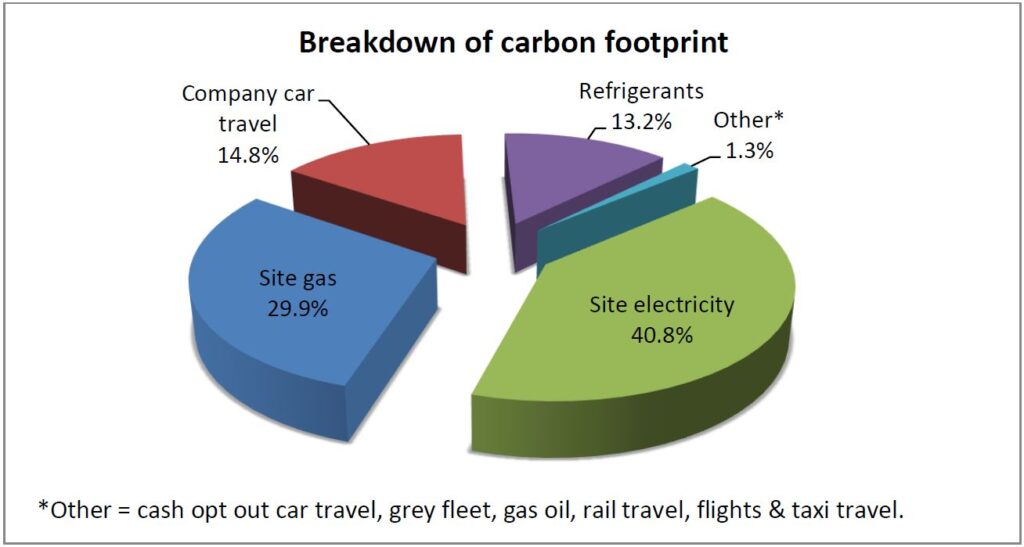

So we looked at what we were already reporting, which was actually quite extensive at least in terms of Scope 1 emissions, we looked at what else we could measure and we looked at where we could bite into the low hanging fruit and went from there.

Straight away we looked into things such as renewable energy purchasing, the feasibility of CHP, circular economy initiatives and incentivising a move away from car travel to and from work. We engaged a consultant to look at our plans and advise us and we looked at feasibly where we want to be. The north star for us was set at net zero as a company so we are currently formulating a plan around that and around making those small incremental changes that will get us there.

It’s not perfect, I’m not saying we’re a beacon of best practise and you should all follow our blueprint. There’s a lot of work to be done; the hardest work is still to be done. But establishing that understanding and will in senior management, is definitely key.

Cultural Change

We had to flip the traditional notions of sustainability on their head. Sustainability isn’t a CSR initiative, it’s not a marketing lever. It’s a business strategy that aligns the company with what customers, employees, investors, and governments are demanding for the betterment of the planet.

“Make sustainability part of strategy” may seem like a throwaway comment, but a lot of companies make the mistake of handing sustainability to one person who often doesn’t sit on the leadership team. They then do their research, bring initiatives to the table and often find that they are blocked / kicked into the long grass / diluted because they don’t align with strategy and don’t align with the senior team and their respective functions, be it finance, purchasing etc.

Sustainability needs to be baked into the strategy of the business and baked into KPIs of the leadership team. It needs to be built around a clearly defined target rather than a woolly “oh we want to be sustainable” generalisation. Set a science based target, make it part of the company strategy, understand it has a cost attached and understand how that target interacts with the core business functions. That’s the only way to succeed.

Sustainability Skills

In an ideal world you would take on a senior leader, with a sustainability degree and deep field experience. In the real world manufacturers aren’t often going to shell out a huge salary on an oven ready senior manager to swoop in and own it from top to bottom.

A workable compromise is to start at mid-level and have an executive sponsor on the leadership team. Find the people with the excitement / passion to drive sustainability from the front. Start with looking at your engineers…ask them to look at product in terms of current carbon footprint and look at producing Environmental Product Declarations. Follow it up with training and then promotion. Alternatively, use your local university, there may be courses with an industrial placement built in. Or get in a consultant and use them as a training resource for your own people.

Diversity

As manufacturers, most of the time we’re not selling to other manufacturers. We’re selling to consumers or other businesses in other sectors. The largest living generation is millennials and Gen Z are now entering the workforce. Hire your customers, hire what your buyers look like. Diversity means diversity of thought. There are studies galore that say sustainability is a top concern of younger employees and buyers. Hire the people who are inheriting the mess we’ve created as they are the ones who stand to benefit from fixing it. You need people with passion to get change done, especially in manufacturing businesses which in my experience are often very slow to change course.

CEO / CFO buy-in

The bottom line is that sustainability is a financial issue. A company’s stock price and access to capital can be enhanced by a proven sustainability program. People are starting to make investment decisions based on sustainability. A survey conducted by PWC states that nearly 80% of investors said ESG was an important factor in their investment decision-making. Green bonds and other green financing options are mechanisms our own customers are increasingly taking advantage of.

Once you stir all that up and conclude that; yes, sustainability is intrinsically linked to finance…then look at the financial sector. It is heavily regulated. Sustainability is becoming a material financial issue so sustainability will, as sure as night follows day, become more regulated, less transparent and will require detailed reporting. Sustainability requirements will become mandatory and intrusive over the next decade. If that doesn’t convince the people at the top of the organisation then nothing will.

Why not wait for legislation?

There is a temptation to “see what happens” or wait for legislation for tell you what to do. However, sustainability is becoming a pre-requisite to bid from certain customers. Customers want sustainability performance from providers.

I guarantee this is a story happening across many industries: One day, a client submits an RFQ in to the business and within the document it is going to ask for an Environmental Product Declaration for the product being quoted. There will be head-scratching and a lot of businesses will write it off as a one-off, submit the quote with that as a non-conformance and the job might not even be lost as a result, it might cost a few points. It will be forgotten about. Then it will happen again, and again, and again. And before long tenders are lost, competitors have moved faster, ground is lost and by the time money has been thrown at it and it’s resolved, it’s already damaged the business.

We’re manufacturers, we make products. The people and organisations buying these products are having the same conversations we’re having now. They want to know the environmental impact of the goods they’re buying so they can factor it in to their own sustainability targets. So for me, step 2, after determining your scope 1 emissions, should be looking at your products.

What should a sustainability strategy look like?

Lord Kelvin is a pretty important figure in the HVAC industry and he once famously said “to measure is to know” To formulate a strategy, it is important to know what your base level is. It is tempting to dive straight in to the low hanging fruit such as energy efficient lightbulbs and waste reduction schemes, but you need to be able to measure where you’ve come from in order to properly document your journey. Select the base elements you want to measure and then select what you want to major on e.g. GHG emissions reduction – based on science based target, renewable energy purchasing, facilities energy efficiency / conservation, circular economy e.g. hardware upgrades, redeployment, recycle & disposal.

Scope 3 emissions (supply chain) are poorly evaluated at the moment; there is a mix of quantitative and qualitative data. Emissions from service providers is the main quantitative one, so start having those conversations with your supply chain now as they need to be ready for it.

Build a project plan of efficiency projects and as previously stated, gain executive commitment. This will unlock inter-organisational co-operation, integration into business strategy and policy & regulatory requirements management. A sustainability team should be formed to enable and co-ordinate initiatives but it is important that business functions own projects relating to their area of expertise. For some it will mean a complete shift in how they do their job, e.g. a shift to a total cost of ownership model in purchasing. This is one of the reasons why sustainability needs executive push and full buy-in from whole business. The key thing other than senior management sponsorship is to find the people with the excitement and passion to drive it.

Offsetting

Many companies use offsetting to appear environmentally friendly. Often, offsetting schemes involve tree planting and are frequently touted as the answer to the climate emergency. Reforestation is certainly absolutely critical and one of the best lines of defence we have against climate change, but this can’t be a substitute for reducing direct carbon emissions.

A tree can up to 20 years to absorb the amount of CO2 that a carbon-offset scheme certifies. What Is often overlooked is that this carbon is not removed entirely, it is trapped in the organic material of the tree / plant. When trees and plants die, whether from fires or logging or simply old age, most of the carbon they have trapped in their trunks, branches and leaves returns to the atmosphere.

Summary

- Sustainability requirements will become mandatory and intrusive over the next decade.

- Some companies are taking a strong lead, others will follow due to a) legislation and b) the fact that customers / investors will increasingly choose suppliers that are taking a lead on sustainability.

- Access to finance will be increasingly driven by sustainability, which will lead to tighter regulation.

- Your customers are feeling pressure from their customers on the sustainability topic. They will pass this pressure down the supply chain. You will see this manifested in requests for EPDs (Environmental Product Declarations) for your products.

- Most global manufacturers have publicly announced sustainability programs.

- In terms of formulating a sustainability strategy, measurement is key, then selecting improvement areas and targets.

- Scope 3 emissions will be the hardest to tackle for manufacturers in terms of measurement / improvement. Engage your supply chain early.

- Executive sponsorship and full business buy-in is key to success.

Sustainability is a business decision, as well an environmental one. You will run out of clients if you don’t take it seriously. Unless you are on a well-defined sustainability pathway (eg Net Zero) via the adoption of science-based targets, you will likely run into big trouble by the end of this decade, perhaps sooner. It’s not too late to make those first small steps to a better future for all of us.