Aisle Containment

How data centre aisle containment can be applied to meet the key objectives in effective data centre design:

- Improving uptime by reducing the dependency on mechanical cooling

- Increasing energy efficiency and lowering PUE

- Controlling capital costs through high density solutions

- Cutting operational costs primarily through energy savings

- Reducing footprint and increasing cabinet density

What is open aisle containment?

Traditional open aisle data centres use perimeter PAC (precision air conditioning) or CRAC (computer room air conditioning) units to channel cold air up through a raised floor void via grilles positioned in front of the IT cabinets. This has significant disadvantages as there is no separation between the supply and return air and significant air movement within the room resulting in poor return air control.

What is cold aisle containment?

In cold aisle configurations the supply air is contained and the hot discharge air allowed to return to the CRAC unit. Because the supply and return air are kept separate, the room temperature can be slightly higher than in open aisle architecture.

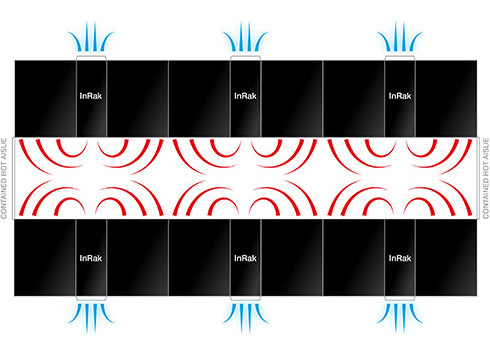

What is hot aisle containment?

With hot aisle architecture, the supply air is directed onto the front of the racks and the hot discharge air ducted back to the PAC units through the ceiling void; this provides better room temperature control and allows for higher return air temperatures, increasing free cooling opportunities.

Even greater efficiencies can be achieved by using in-row hot aisle containment such as the InRak™. This configuration reduces airflow with a controlled cooling path and, because airflow is predominately horizontal, does not require floor and ceiling voids. All of the energy is applied to cooling the racks, not the room.

Rear-door compact hot aisle coolers such as the OnRak™ which are fitted directly to the discharge of the cabinet similarly shorten the air path and air movement.

The application of aisle containment provides much closer management of the supply and return air paths within ASHRAE guidelines which calls for supply temperatures below 27°C. By effectively managing air flow, higher air temperatures can be returned to the cooling coil to drive heat exchange and maximise free cooling opportunities.

Open vs Cold vs Hot aisle containment

Let’s see this in practice based on a typical 500kW facility:

In an open aisle configuration, supply and return air temperatures will typically be set at 12°C and 24°C respectively. Because air mixing occurs, the room has to be kept at an artificially low temperature.

By introducing cold aisle architecture where the hot and cold air are separated, the supply air temperature can be increased to 17°C and the return air temperature to 27°C. The room temperature is governed by the return air temperature back to the PAC units.

With both of the above configurations rack load is 5kW, meaning that 100 cabinets will be required to satisfy the 500kW load.

Real benefits start to be achieved when hot aisle architecture is introduced. Supply and return air temperatures can be increased to 22°C and 35°C and, with no air mixing within the room, rack load can be increased to 10kW, requiring only 50 cabinets to satisfy the 500kW load. This creates the opportunity for an additional 420kW of IT load within the space. Room temperature is governed by the supply air temperature leaving the PAC unit. With higher cooling output per footprint, the InRak™ in-row cooling system frees up further space within the data centre due to an increase in cooling load per square metre.

The highest efficiencies are however achieved using a compact hot aisle configuration. With rear-door OnRak™ cooling units, the air-on temperature to the cabinet is maintained at 27°C in line with ASHRAE guidelines; the heat exchange occurs at the rear of the cabinet and provides a high discharge temperature (in this case 42°C). This architecture halves the number of cabinets required to meet the 500kW load to 25 with a high rack load of 20kW per rack. This creates an additional opportunity for 1880kW of IT load within the space.

Summary

Open aisle configurations provide limited opportunity for free cooling due to the lower return air temperatures required to keep the room artificially cool. Based on our typical 500kW installation, an open aisle data centre will operate in full free cooling mode for just 1% of the year, with a requirement for some form of mechanical cooling for 51% of the year. These figures reduce to 6% and 32% respectively when cold aisle containment is implemented.

Hot aisle containment will further increase free cooling opportunities with the InRak™ capable of delivering full free cooling for up to 25% of the year (18% of the year in mechanical cooling mode) and the OnRak™ delivering free cooling for up to 20% pa and relying on mechanical cooling only for just 11% of the year, with a high percentage of concurrent free cooling that maximises the part-load efficiencies of components.